The deposits are usually used for wine fermentation. It is the moment in which the must will become wine. We are going to talk about the most common deposits:

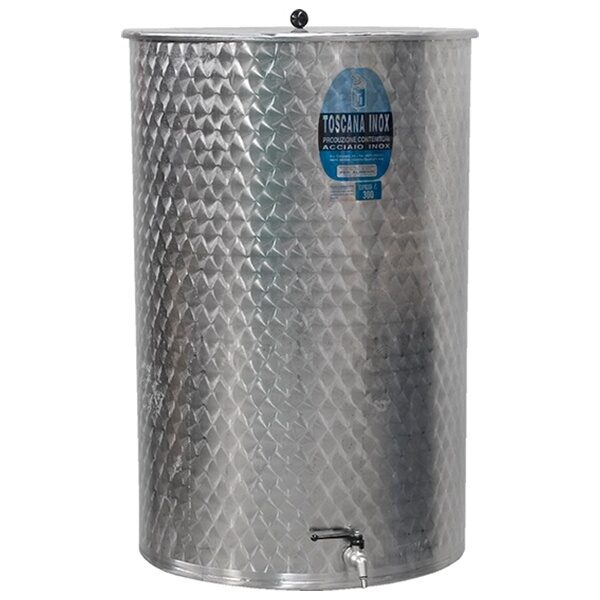

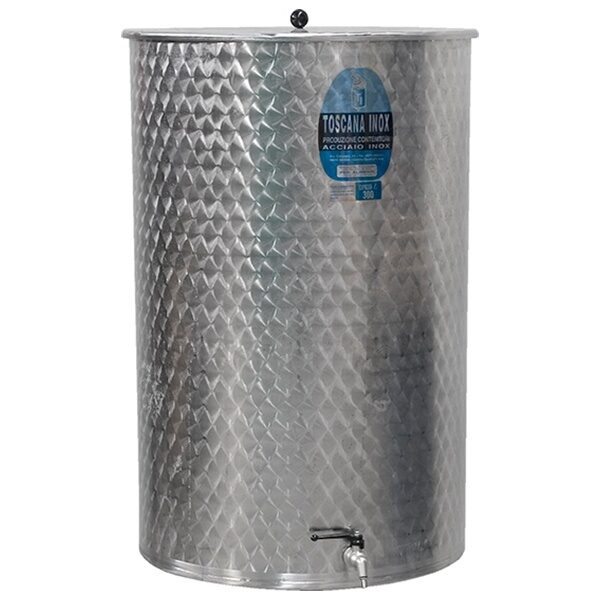

Stainless steel tanks: Currently, the stainless steel It is one of the most common materials for the must fermentation tanks. This material is the most appropriate, durable and safe because it allows to better control the temperature and obtain fruity wines. The wine does not affect it in any way, so it is one of the most used in the wineries.

Wood deposits: This type of tanks should be located in places where there is good temperature control. They are usually used for wines chosen from the winery. In addition, their size is usually smaller than steel tanks and it must be taken into account that they are more delicate and require more hygiene treatments.

Concrete tanks: These types of tanks have been used for many years and it is still very common to find them. Although they are easy to clean and last a long time, their main disadvantage is the difficulty of evacuating the heat produced during fermentation.

In short, each of the deposits mentioned has advantages and disadvantages. The choice of Fermentation tanks The wine depends on many factors and above all, the result you want to achieve and the personality that each winery wants to print to your production.

Stainless steel tanks for wine making

Form of deposits

Tanks are available in a wide variety of sizes, from small 75 liter tanks to 10.000 liter tanks.

The size chosen already depends on the needs of the winery. Small tanks are the ones that present the most advantages, since temperature control is easier, they allow musts of different qualities to be vinified independently, and in the case of red vinification, the maceration will be more homogeneous and intense. For this reason, it is always tried that the tanks for fermentation are as small as possible.

It is recommended not to use deposits of more than 50.000 liters for vinification, since deposits of this size and above are usually used for storage.

Interior and exterior deposits

The tanks can be located indoors or outdoors. The outdoor tanks correspond to large volumes, and are normally used for storage, and are not used in winemaking due to the difficulty of controlling the temperature outside.

But there are also the so-called self-vinifying or continuous vinification tanks, which due to their large size, must necessarily be installed outside.

The interior deposits are the most used. They can be located on the surface or buried.

The buried ones were built in the past as security deposits in case of breakage of those on the surface, and to make better use of the space in the cellar. Although today they are no longer used because temperature control is very difficult, so they are used only for storage.

Open or closed tanks

Fermentation tanks can be opened or closed. Both in one case and in the other, in the tanks destined to vinify red, the hat can remain floating or submerged by means of grids.

Open tanks were used in small artisanal wineries, where short vats were used for wines with a high alcohol content. This system was very common in wineries, but today it has practically disappeared.

The mouth of the tank was covered with a nylon cloth attached to the edges to prevent the protective CO2 from being completely eliminated. This system made fermentation fast, intense and complete, especially for high alcoholic degrees, all due to better aeration and natural temperature control.

Although there are many more drawbacks than advantages, since in this way alcohol losses were caused, danger of oxidation, increased volatile acidity and ethyl acetate, risk of fermentation stops, inhibition of Melo-lactic fermentation in cold years, etc.

The tanks that are currently used are closed tanks, which have a hermetic closure and an inserted adoring slipper that lets out the CO2 produced in fermentation, thus preventing the entry of air. Airtightness is essential in storage tanks. Some of the advantages of this system are:

- The selective hermetism avoids the contact with the air, allowing therefore the exit of CO2 but not the entrance of air. The CO2 forms a protective upper layer in the vacuum that has been left when filling the tank, which is not displaceable by air as it occurs in open tanks.

- Heat is perfectly preserved even in cold years.

- They can be large capacity and vinify large volumes.

- They facilitate malolactic fermentation.

- They give good quality press wines.

- They can be used in the conservation and storage of wines.

In any case, the closed tanks also present some drawbacks, but fortunately they can be avoided by aeration and temperature control systems.

- As fermentation takes place sheltered from the air, there is a risk that it will stop due to asphyxia of the yeasts, since they can consume nutrients and, however, not consume sugar, with which there comes a time when they cannot continue living, being necessary pump-overs with aeration to obtain a good multiplication of the yeasts.

- Heating closed tanks is important and can be dangerous for the end of fermentations.

CHARACTERISTICS OF CLOSED DEPOSITS

We can find different types of closed deposits more frequent in the cellars, some of them versatile that are used for multiple tasks, and others specific for some wine operation:

- Traditional deposits. They are normally made of AISI-316 or 304 stainless steel with the last ferrule in 316, they can have cooling jackets and are generally flat-bottomed.

They are mainly used to ferment whites and rosés, for preservation and storage. If they are used for red wines, they must have a large manhole at the bottom.

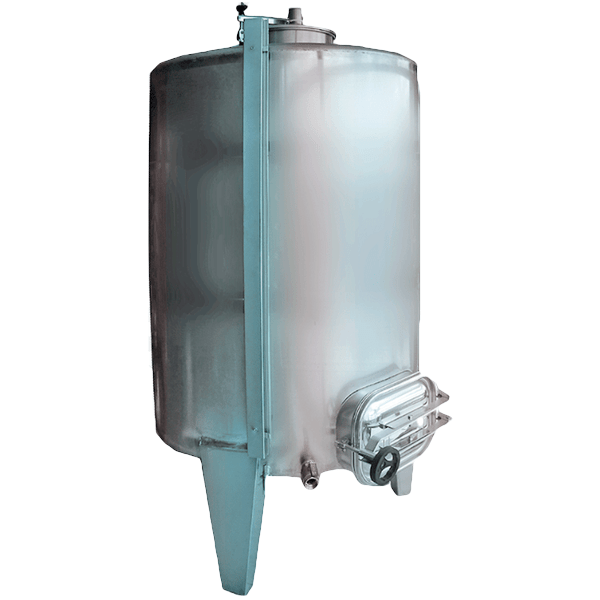

- Self-emptying tanks. They are made of AISI-304 stainless steel except for the last ferrule, which is made of 316. They are equipped with a cooling jacket at the height of the cap and mechanisms to carry out automatic remounting.

They can have a conical bottom, deflected towards the front, and have an endless screw-type pomace extraction system or a propeller. Sometimes they have a set of grids at the bottom to facilitate bleeding.

- Special tanks. They are deposits of vertical structure, contain an internal stirring system or automated remounting to facilitate the homogenization of the pastes in the vinifiación in red.

- Deposits always full. They have a mobile cover that can be lowered to the same level of liquid. They can be used for winemaking and storage, but their most common use is as a wine container for filling.

- Deposits autovinificadores. They are made of a tank in horizontal position, supported on two supports that turn it. By this rotation movement the maceration is increased and pumping is not necessary. They are used for prefermentative macerations of whites and rosés, as well as in the fermentation of red wines.

- Isothermal tanks. They are completely isolated deposits that are used for chemical stabilization. We could also include in this group the buffer tanks of the cold equipment, which, without being totally isothermal, are isolated to achieve the least loss of frigories.

Some are divided into two compartments: the hottest water from the jackets arrives in one before passing through the cold compressor, and the cold water from the compressor arrives in the other compartment. They can be insulated plastic or stainless steel.